Tin Plating service in Dubai, UAE

Tin Plating On Copper

Skye metal coating LLC offers tin plating for copper parts. We are one of the leading tin electroplating suppliers for top 5 copper manufacturing companies in the UAE. Unlike a raw copper bus bar, tin coated copper bus bar provides a flexible and ductile barrier that doesn’t readily oxidize when exposed to oxygen or other elements. In comparison to a copper surface, which quickly loses conductivity due to oxidation, the tin coating maintains a more enduring and consistently conductive performance. Although tin may eventually experience a decrease in conductivity, its formation of a relatively thin oxide layer ensures that it remains reasonably conductive over time.

Why use Tin Plating?

Tin is characterized by significant electrical potential. It is extremely conductive, solder-able, self-lubricating and compatible with food. The surface of tin has multiple functional properties such as corrosion protection, chemical resistance, high ductility and pretty decent layer thickness distribution. Its silver-white appearance makes it an attractive alternative to silver.

Having all of its functional and decorative properties, tin layers can be used in various industrial sectors including electronics and electrical engineering, automotive and food industries, and in mechanical engineering. When combined with other layers, the functional properties of tin layers can be further modified.

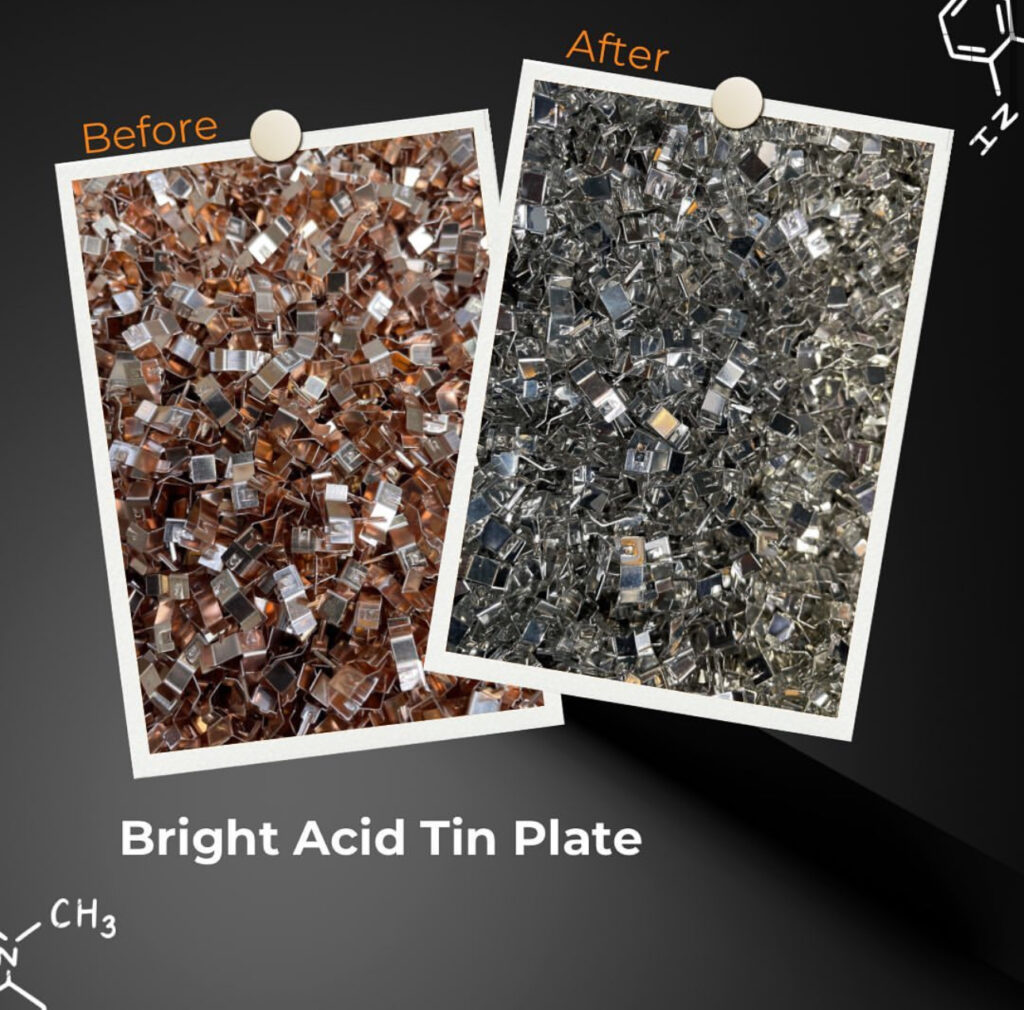

Bright Tin Plating Service

Tin plating is an electroplating process which deposits a thin layer of tin on a metal surface. Generally, tin is plated directly on the Copper material without an undercoating. Tin plating is commonly used in corrosion protection and solderability. They are used on copper bus bar to protect the bus bars and to help the solder-ability of copper. Tin deposits are widely used in the production of food processing and shipping equipment (containers). In addition, they are also used in pump parts, automotive pistons, copper & steel wire, plating of electrical components and printed wiring boards. Tin is appealing to the food processing industry as it is a non-toxic, ductile and rather corrosion-resistant metal. The excellent ductility of the metal allows a tin coated base metal sheet to be formed into a variety of shapes without any damage to tin itself.

Advantages of Industrial Tin Plating in Dubai

Tin Plating service offers numerous benefits, including optimal surface coverage, corrosion protection, and enhanced electrical conductivity.

One of the key advantages of tin plating copper is its superior corrosion resistance compared to other metals. The thin layer of tin acts as a protective barrier, shielding the underlying metal from oxidation and environmental factors. This corrosion protection extends the life of the metal part, making it suitable for industries including electronics, automotive, and telecommunications.

Among the different types of electroplating, tin coating also provides excellent solderability, especially when used in tin-lead alloy compositions. The molten tin deposit forms reliable contact surfaces, ensuring good electrical conductivity and strong solder bonds. This makes it an ideal choice for electrical connectors, printed circuit boards, and semiconductor components.

In addition to corrosion resistance and solderability, tin coating offers benefits such as an attractive appearance, lubricity, and compatibility with hot-dip processes. The thin layer of tin provides a shiny finish, enhancing the aesthetics of the metal part. The tin plated copper busbars are often preferred. Its lubricity reduces friction and wear, making it suitable for applications where smooth surfaces are desired especially in electronics industry. Furthermore, tin plating metals is compatible with hot-dip processes, allowing for the deposition of additional protective coatings or treatments.

In summary, tin plating in dubai is a widely utilized metal finishing process that provides optimal surface coverage, corrosion protection, and enhanced electrical conductivity. With its numerous benefits, including excellent solderability, corrosion resistance, and compatibility with various industries, plating satin is a preferred choice for extending the life and improving the performance of metal components.

Is this Tin Plating near me?

Yes. Call us today! 0507045388

Frequently Asked Questions

Question: How does tin plating prevent rusting?

Answer: Tin plating prevents rusting by forming a protective barrier on the metal surface. When tin is applied as a coating to a substrate, it creates a thin layer that acts as a physical barrier, preventing direct contact between the underlying metal and environmental factors such as oxygen and moisture. This inhibits the oxidation process, which is a key factor in the formation of rust on metal surfaces. Additionally, tin itself is resistant to corrosion, further contributing to the prevention of rusting on the coated material.

Question: What is the difference between tin plating and zinc plating?

Tin plating involves depositing a layer of tin onto a substrate, providing corrosion resistance and a lustrous appearance. This process is often utilized in electronic components and applications where aesthetic considerations are paramount.

Zinc plating, on the other hand, is a method that deposits a layer of zinc onto a substrate. It primarily serves as a sacrificial anode, offering galvanic protection against corrosion. This makes zinc plating particularly advantageous in industrial settings where durability and corrosion resistance are critical.

Question: What industries uses tin plated copper bus bars?

Answer: Electronics, Power Distribution, Telecommunications, Automotive, Renewable Energy, Aerospace, Industrial Equipment and Manufacturing.

Question: What type of tin should I use on copper busbars?

Answer: For copper busbars, it is recommended to use electrolytic or pure tin due to its superior conductivity and corrosion resistance.

Question: How will the price of tin plating be calculated in Dubai?

Answer: Prices will usually be less than AED 10 per kg depending on the condition of your current copper item. Feel free to call us at 0507045388 for exact quote.

Standard Specification No:

ASTM B545 – Electrodeposited Coatings of Tin.